موقعك الحالي:صفحة رئيسية>المنتجات

2009year7month1day The control schemes in previous literatures, including detuned multi-loop PID control, model predictive control (MPC), robust control, adaptive control, and so on,

Read More

2021year7month26day In this paper, a composite control strategy based on MPC-DO is put forward to realize the control of the three-input-three-output ball mill system. The

Read More

2012year6month1day The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial

Read More

2017year8month27day Abstract: Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while

Read More

1999year6month1day The ball mill grinding circuit studied consists of the ball mill, the slurry sump and hydrocyclones. By combining the models of each of these equipment a total grinding

Read More

2013year7month4day Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while guaranteeing

Read More

2022year12month1day Control of a closed dry grinding circuit with ball mills using predictive control based on neural networks - ScienceDirect Volume 5, December 2022, 100064

Read More

1999year6month1day In the present paper the ball mill model, together with the hydrocyclone separation system model is used in a simulation study to generate a response surface

Read More

2005year4month1day Control studies on a laboratory ball mill grinding circuit are carried out by simulation with detuned multi-loop PI controllers, unconstrained and constrained model

Read More

Costea et al. developeda fuzzy logic-based control architecture in which the ball mill grinding process was considered as a single input and single output system (SISO) and the total feed into the mill was maintained by

Read More

Costea et al. developeda fuzzy logic-based control architecture in which the ball mill grinding process was considered as a single input and single output system (SISO) and the total feed into the mill was maintained by

Read More

2023year9month23day The primary purpose of this article is to use the ground particle size diagram and acoustic signal in ball mill control, and model their relationship based on the least squares method. As a result ...

Read More

2019year11month13day Luo Wenshun.The Design of Large Ball Mill Control System[D].Anshan:University of Science and Technology Liaoning,2016. 3 王越,杨世亮,邵爽,等.大型球磨机钢球配比试验研究与工业应用[J].

Read More

2009year7month1day Ball mill grinding circuits are essentially multi-variable systems characterized with couplings, time-varying parameters and time delays. The control schemes in previous literatures, including detuned multi-loop PID control, model predictive control (MPC), robust control, adaptive control, and so on, demonstrate limited abilities in control ball mill

Read More

2020year7month25day 摘要: 这是一篇矿业工程领域的论文。. 选矿厂节能降耗需求强烈,球磨机负荷检测是实现磨机控制、优化磨矿流程的关键技术。. 本文归纳了近year来磨机负荷的检测方法:压差法、磨音法、振动法、功率法、超声波法、基于多源信号融合的间接检测方法;总结并 ...

Read More

2013year7month4day Operation aim of ball mill grinding process is to control grinding particle size and circulation load to ball mill into their objective limits respectively, while guaranteeing producing safely and stably. The grinding process is essentially a multi-input multi-output system (MIMO) with large inertia, strong coupling and uncertainty characteristics.

Read More

2023year8month15day 球磨机是物料被破碎之后,再进行粉碎的关键设备。这种类型磨矿机是在其筒体内装入一定数量的钢球作为研磨介质。它广泛应用于水泥,硅酸盐制品,新型建筑材料、耐火材料、化肥、黑与有色金属选矿以及玻璃陶瓷等生产行业,对各种矿石和其它可磨性物料进行干式或湿式粉磨。球磨机适用于粉 ...

Read More

2015year8month1day This paper presents a review of the current state of technology on improved controls and fault diagnosis methods applied to mills. An understanding of the mill system, control issues and major faults influencing the mill performance are discussed. Control strategies applied for mill controls such as control using estimated pulverized fuel flow ...

Read More

The extremely high centrifugal forces of Planetary Ball Mills result in very high pulverization energy and therefore short grinding times. The PM 100 can be found in virtually all industries where the quality control process places the highest demands on

Read More

2016year2month1day Start ball mill lime timer. The lime control valve should be pulsing open for 3 seconds every 30 seconds (after calibration of all lime timers). ... Normal Shutdown Sequence of Ball Mill and Grinding Circuit . Shut off cyanide metering pump. Put weight controller into MANUAL mode and turn controller output to 0%. Run the ball mill for 15-30 ...

Read More

Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, ... H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball

Read More

The six ABB GMDs, which are the most powerful mill drive systems on the market are all now in continuous operation. Two 28 MW gearless mill drive systems (GMDs) are operating in the mine's 40 foot SAG mills and four

Read More

1983year1month1day Prediction of mill RTD from mill design and operating variables. University of Utah ball mill grinding project report,January. Rowland, C.A. and D.M. Kjos (1978). Rod and ball mills. Mineral processing plant design, Mular, A.L. and R.B. Bhappu, eds., AIME, New York. Siddique, M. (1977). A kinetic approach to ball mill scale-up for dry and wet ...

Read More

2023year6month20day A controller for a closed-circuit ball mill with a high-efficiency separator was providing adequate feed control for T-I cement (the main product), but poor control for T-III, masonry, and slag ...

Read More

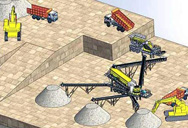

2017year8month27day The ball mill grinding process is mainly composed of a ball mill, a hydrocyclone cluster, a sump, a slurry pump and an ore bin. The schematic diagram of this process is shown in Fig. 1. Fig. 1 Schematic diagram of ball mill grinding process. The variables of this process shown in Fig. 1 are ex-plained as follows: W

Read More

2012year6month1day An improved control strategy is proposed to control ball mill grinding circuits for energy saving and pollution reduction. A two-layer optimization architecture combined by particle size optimization layer and energy optimization layer is developed, ...

Read More

2016year12month23day Process IQ is an expert in implementing control systems for SAG and Ball milling circuits, making use of advanced stabilisation and optimisation strategies developed by Evita. welcome to my ...

Read More

2022year3month6day A ball mill is important grinding equipment in a concentrator, and the accurate detection of the load status ensures that the ball mill runs in the best state, which helps optimize the grinding process, ensure the stable operation of the ball mill equipment, and save energy. The current mainstream detection methods cannot easily detect the

Read More

Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or metallic balls or rods ...

Read More

الصين -تشنغ تشو -المنطقة الوطنية للتنمية الصناعية للتكنولوجيا المتطورة، جادة العلوم رقم 169.

الصين -تشنغ تشو -المنطقة الوطنية للتنمية الصناعية للتكنولوجيا المتطورة، جادة العلوم رقم 169.