موقعك الحالي:صفحة رئيسية>المنتجات

2023year5month2day material crushing by mechanical ways such as extrusion, breaking, splitting, shearing, impact, and grinding. It is widely used in mining, metal-lurgy,construction,municipalengineering,chem-ical industry, food, and other industries.

Read More

2017year3month4day Crushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in

Read More

2022year1month14day Commonly used crushers include jaw crusher, impact crusher, hammer crusher, cone crusher, etc. This article will introduce the working principles of these four

Read More

2023year8month25day The working principle of a jaw crusher is straightforward: the material is fed into the crushing chamber, where it's crushed between two jaws that move back and

Read More

2007year1month1day Figure 1 gives a rough estimate. This section deals with “single-particle crushing” as an important microprocess in the field of comminution. It is a part of the

Read More

2007year1month1day Georg Unland Add to Mendeley https://doi/10.1016/S0167-3785 (07)12007-8 Get rights and content Publisher Summary This chapter deals with “single

Read More

2016year2month17day Working Principle of Crushers. On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the

Read More

2023year6month30day The subject of this study is crushing equipment. It is a complex of units designed to reduce the fraction of ore and non-metallic solid materials. It is also designed to make them more symmetrical in

Read More

2010year1month1day In material analysis laboratories, where many investigations are performed, crushing equipment can be more complex or more complete. To replace manual

Read More

2021year8month15day The most important research topics are (i) mass balance control of crushing circuits; (ii) crushing circuit flowsheet optimization, (iii) mechanistic

Read More

2023year3month11day Crushing Equipment / March 11, 2023 / 5 minutes of reading. An impact crusher is a machine used to crush materials by impact energy. It works by feeding the material into a rotating rotor, which is

Read More

2020year2month19day Crushing Principle. 1.Breaking method classification. ... Common problems of crushing equipment Dec 12, 2019 Brief Introduction to Cemented Carbide Roll rings Jul 9, 2019 ...

Read More

2021year2month5day centrifugal impact crushers have one accelerator and work on the principle of "stone on stone" with a vertical shaft. Such crushers were first used by Barmac Associates (New Zealand) in the 70s. XX century [11]. In most tasks, the crushing and grinding equipment uses the principle of destroying the stone-to-stone material.

Read More

2007year1month1day This chapter deals with “single-particle crushing” as an important microprocess in the field of comminution. The term “crushing” is related to a certain kind of comminution. It depends on the material properties and the grain size distribution of the feed and/or the product. It is a part of the macroprocess that happens inside the ...

Read More

2023year8month25day The basic principle of a crusher is to apply mechanical force to a material to crush it into smaller pieces. Crushers use a combination of compression, impact, and shearing forces to achieve the desired size reduction. The following are the most common types of crushers used in the size reduction process: 1.

Read More

2022year3month4day Several types of crushers are capable of crushing rocks up to 1.5 m (60 inches). 1.1 Basic principles of crusher selection [3] The period of operation The specification of stone materials The nature of stone materials 1.2 Factors to consider when choosing a crushing equipment [3] 1. Economic indicator 2. Technology indicator

Read More

Contribute to dinglei2022/en development by creating an account on GitHub.

Read More

2010year1month1day In material analysis laboratories, where many investigations are performed, crushing equipment can be more complex or more complete. To replace manual crushing, there are automatic crushing devices such as the mortar crusher, whose operating principle is the same as an agate mortar and pestle, except that crushing is mechanized.

Read More

2023year2month23day The cone crusher working principle involves the eccentric motion of the main shaft. This motion is created by the rotation of the main shaft, which is supported by a bearing located at the top of the machine. As the main shaft rotates, it causes the mantle to move back and forth against the concave, crushing the rocks and ores between them.

Read More

2015year5month13day Prediction of crusher performance has been focused on, since crushing is a vital process for both industries. In this thesis a method for prediction of cone crusher performance is presented.

Read More

2021year8month11day 2012). Additionally, from the theoretical point of view, crushing per-formance in the quarrying and mining industries have different optima (Lee and Evertsson, 2011). This work opens with a brief review of the mechanical principles of cone crushers. Then, in the following sections, works available in the

Read More

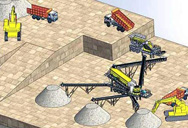

2021year8month27day The prop form of the crushing and screening equipment, the ease of installation, and the amount of foundation steel and concrete are also important factors should be considered in the selection. The movable steel structure support has simple construction, easy assembly and disassembly, rapid transfer, and small foundation

Read More

2023year12month1day In comparison to pressure crushing, the principle used here is impact crushing. ... This kind of impact stone crusher is a kind of high-efficient strong coarse and mid crushing equipment we ...

Read More

2022year11month21day Due to the crushing principle, cone crusher has better grain shape than jaw crusher. Generally, you need shaping equipment after jaw crusher for better grain shape. And cone crusher can be used for shaping because of the adoption of lamination crushing principle, which makes the final products have good cubical shape. 8. Different

Read More

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

Read More

2020year6month3day What is Crushing Equipment? Crushing equipment is used by a wide variety of industries to refine raw materials to a more manageable size. Here are just a few of the industries that rely on crushing equipment. ... The Symons Principle. Many cone crusher manufacturers use the Symons Principle to produce more powerful and efficient crushers.

Read More

2022year5month24day 5.Foundation and pillar. The supporting methods of the crushing and screening equipment, the difficulty of installation and the construction amount of the steel and concrete are also the factors to be considered when selecting the machine. The movable steel structure has the advantages of simple construction, easy assembly and

Read More

2018year11month19day 5.Crushing and grinding equipment ... Principle of grinding is mainl y impact and abrasion. In general, output of grinding mill is . powdered form of ore and economically viable for mineral sorting.

Read More

2015year5month30day the development trend of agricultural straw fine crushing equipment. II. Straw Principle and Structure of Fine Crusher Traditional straw fine crusher working principle is: the biomass straw cut off by the other crushing machinery such as Guillotine cutting machine are fed into crushing chamber by feeding mouth, through high- ...

Read More

2018year11month7day Principle 1:More Crushing and Less Grinding. Crushing is mainly realized by the crushing equipment's extrusion and impact on the material. While grinding mainly depends on the impact, milling and denudation of the grinding equipment. There into, grinding is an operation with low efficiency and high energy consumption.

Read More

الصين -تشنغ تشو -المنطقة الوطنية للتنمية الصناعية للتكنولوجيا المتطورة، جادة العلوم رقم 169.

الصين -تشنغ تشو -المنطقة الوطنية للتنمية الصناعية للتكنولوجيا المتطورة، جادة العلوم رقم 169.